Groschopp News & Press

It moves! – Individual drives for conveyor techniques

Groschopp AG, Viersen offers customer-tailored solutions for diversified applications

Fast and efficient material flow and an uninterrupted processing of goods within the production process are essential. Efficient and reliable drive solutions are an absolute requirement to guarantee a trouble-free production without downtime. Groschopp AG knows the particular challenges in the conveyor techniques only too well and offers customer-tailored drive solutions for world-wide applications.

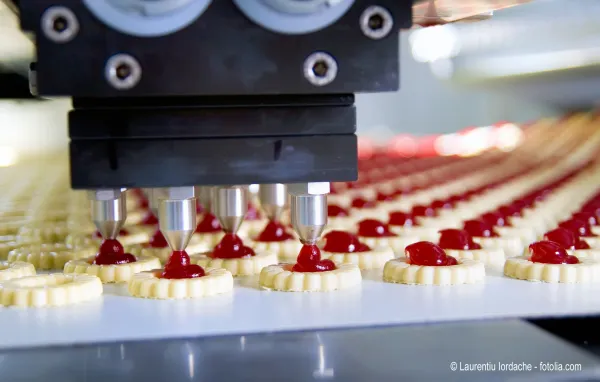

The name 'Groschopp' is synonymous for drive techniques of the highest standard for the past 95 years. The company, with headquarters in Viersen, identifies itself as a 'bespoke tailor' in drive solutions and specializes in customer-tailored solutions, particularly in conveyor techniques. Groschopp manufactures drives, motors and controllers, as well as complete drive solutions for small and medium sized equipment, custom-fit for special requirements and all needs posed by individual customers. The foodstuffs-, packaging-, pharmaceutical- and chemical-industries in particular, as well as selected special areas of applications in manufacturing systems engineering like filler rod feed, enveloping or printed circuit production, all rely on drive solutions in the area of conveyor techniques, provided by Groschopp.

Nowadays, conveyor techniques comprise far more than just a mere transport of goods from one process step to the next. Included in the typical applications are also positioning, dosing and sorting. Check-weighing machines are a special design: a weighing unit detects the weight of a product without the conveyor belt having to stop. Depending on the objectives of the customer, diverse demands on performance, control and design of a particular drive are made. To guarantee constant transport, cost-efficient AC- or three-phase-motors (respectively an induction- and squirrel-cage-rotor) are often enough. However, for high dynamic and exact positioning, an efficient servo-drive is needed. This will accelerate and decelerate quickly and will stop at the exact position determined by the customer. Most of all, cleaning drives requires specific demands. Groschopp, as member of the EHEDG (European Hygienic Engineering & Design Group), develops and produces drives, which fulfill the EHEDG Guidelines and all requirements of a Hygienic Designs.

Additional factors like temperature, especially for applications in cold storage rooms in the foodstuffs industry, or the period of application for shift-, continuous- or irregular operation times of the equipment, as well as requirements on IP-protection classes, are dealt with at the consultation, development and design stages of such drives for the conveyor techniques. Groschopp has adapted individual customer requirements and offers a broad range of drives, from individual products via the integration of drives into an already existing controller concept, up to complete solutions. Smaller and medium sized batches in lots of 5 to 1,000 units can be realized. International standards and guidelines like CE, UL-recognized and REACH & RoHS are adhered to. Groschopp has planned in future to intensify and expand its position as supplier of complete drive systems, especially for Hygienic Design drives.

Pressestelle: Köhler + Partner GmbH * Brauerstraße 42 * D-21244 Buchholz i.d.N.