Groschopp News & Press

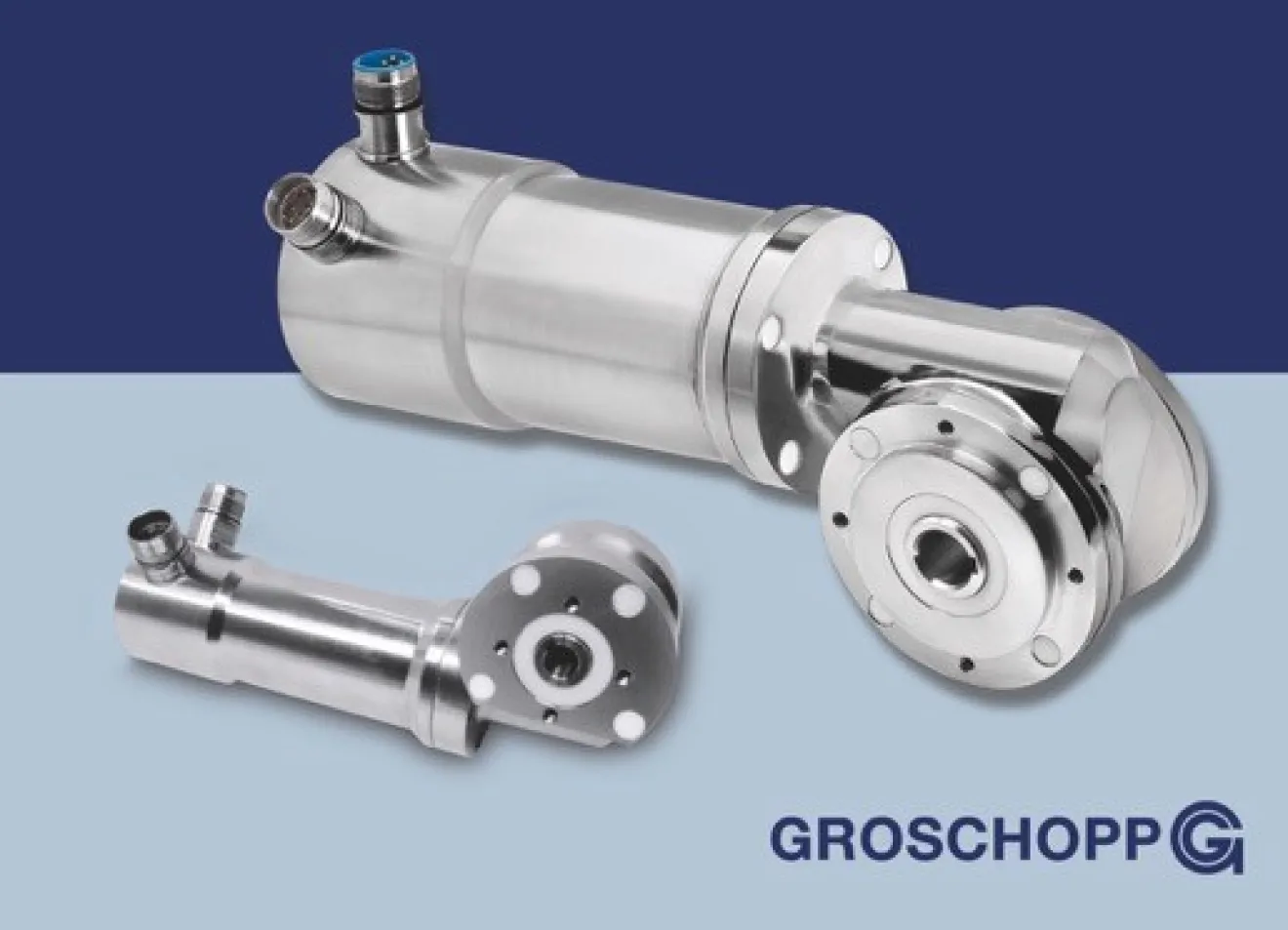

The de-centralised servo-motor ‘NI’ made by Groschopp is encased within a robust stainless steel housing - an ideal prerequisite for any application in areas with strict hygienic requirements.

Whenever bread dough is kneaded, Pizza is topped or apple juice is bottled in the foodstuffs industry, hygiene has top priority. That is why components need to be (i) carefully designed with hygiene in mind, (ii) are easier to clean and (iii) can withstand abrasive cleaning agents.

Groschopp AG provides motor-gear combinations for such applications with their ‘Silver-Line’-models. These are compact-built stainless steel drives, comprising a housing with rounded edges. This design “without edges or corners” prevents accumulation of particles of dirt.

Surfaces are extremely smooth and polished, reducing further any surface roughness. In that way, the drive solutions are fulfilling all hygiene demands, especially in the area of corrosion resistance. However, using stainless steel for the motor housing causes a problem: the material is very resistant to corrosion, but it also has the disadvantage of low heat conductivity. Hence, in order to achieve the required output of the respective motor size, the entire concept of the motor layout needs to be absolutely well-engineered.