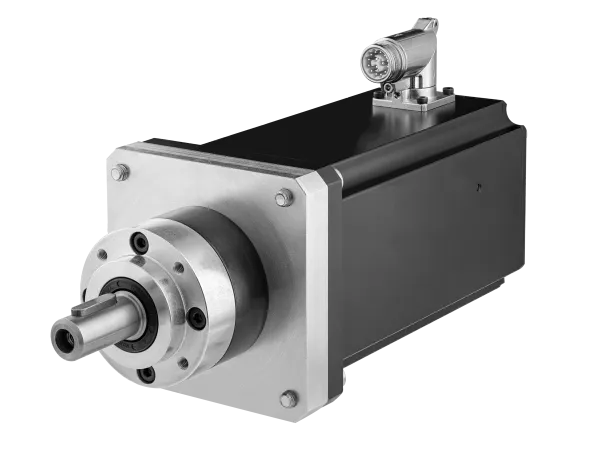

BLDC Brushless Motor

Groschopp offers the right drive concept for every application

One of the most important questions in application planning is that of the suitable drive: The right one for the application must be selected from many different electric motors. With its broad portfolio of AC motors (in three-phase or AC versions), servo motors, DC motors and BLDC motors, Groschopp has the right drive solution for every application. Depending on the application, the question of brushed or brushless motors may arise. We would like to briefly introduce you to the advantages of a BLDC motor and the alternatives available.

Drive systems from Groschopp: Whether BLDC brushless motor or brushed motor - Groschopp AG has the tailor-made solution for every application!

What is a BLDC motor and what advantages does it offer?

BLDC brushless motor stands for brushless DC motor. Strictly speaking, this is not so much a DC motor, the design is more similar to a three-phase synchronous motor, in which the current is supplied by suitable electronics. For this purpose, the rotor is equipped with permanent magnets. The stator consists of coils, which are controlled by suitable electronics so that a magnetic rotating field is generated. Brushed DC motors are widely used in industry, after all they offer interesting advantages such as easy installation and control, high starting torque, wide speed control range, overload capability and more. However, brushes wear out quickly during operation due to friction (depending on application frequency, vibrations, speed, power, etc.) and the risk of sparking as well as dust formation complicates or prohibits their use in some areas, such as clean rooms, textile industry or optical applications.

A BLDC brushless motor offers interesting advantages for your application:

- No spark and dust formation: Since no carbon brushes are rubbed off with a BLDC brushless motor, there is no risk of brush fire or dust formation, making the motor very suitable for sensitive areas.

- Long life & low maintenance requirements: A BLDC brushless motor has no wear on the sliding contacts and therefore has a longer service life (10,000 operating hours and more), which makes it very interesting especially for continuous operation. In addition, it does not contain any wearing parts except for the bearings, which massively reduces the maintenance requirements.

- High efficiency: Not only can a BLDC brushless motor operate at higher speeds than a brushed motor, it also consumes less energy and generates less heat, making it very efficient.

Alternatives to the BLDC motor: Induction motors from Groschopp

With the electronically commutated servo motors of the EGK series, Groschopp offers electric motors that have been optimized for sinusoidal current flow. They produce a uniform constant torque, especially at low speeds, and also score points for high power density and positioning accuracy as well as very good energy efficiency. Thanks to an integrated controller, space requirements and wiring effort can also be reduced to a minimum.

Groschopp induction motors are a brushless and also very cost-effective alternative. These have a multi-strand distributed winding in the stator, which creates a rotating field when supplied with alternating or three-phase current. The stator's rotating field induces a voltage in the rotor, which in turn generates a magnetic field in the rotor. The interaction between the magnetic field of the stator and the rotor causes the AC motor to generate torque.

Other advantages of the Groschopp alternatives to the BLDC brushless motor:

- Wide range of housing motors and built-in motors for every application purpose

- 2 or 4 pole drive (2,4,6 and 8 pole drive)

- Fixed speed (2-pole: 2800 min-1, 4-pole: 1400min-1) for operation directly from mains (f=50Hz)

- Speed between 90 and 30,000 min-1 when operating on a frequency converter

- Various individual configurations possible

- Combinations with gear units for gearmotors can be realized

BLDC Motor and more: Groschopp is your reliable partner for individual drive solutions

The optimum drive for your application - Groschopp sees itself not only as a manufacturer, but also as a partner for designers and engineers in machine and plant construction. With high-quality and sustainable solutions, we support you in the realization of your projects.

- Competent advice: BLDC brushless motor or brushed design? We provide you with individual and expert advice on the selection and design of your drive systems and, if desired, also develop complete solutions for small and medium-sized systems.

- Innovative products: Thanks to our research and development, we can always offer you innovative products when standard solutions are sufficient. In doing so, we not only adapt existing models precisely to your operating needs, but also research new drive solutions in close cooperation with universities and industrial partners.

- Sustainability as a corporate concept: The defining motto of Groschopp AG is sustainability through quality. To this end, we offer you highly resilient and durable products such as the BLDC motor, pay attention to the responsible use of resources in research, development and production, and disclose our efforts with regular certifications and sustainability reports.

Do you have any questions about BLDC brushless motors or DC motors? Would you like support in planning your application? Then contact us - our specialists are always happy to help!