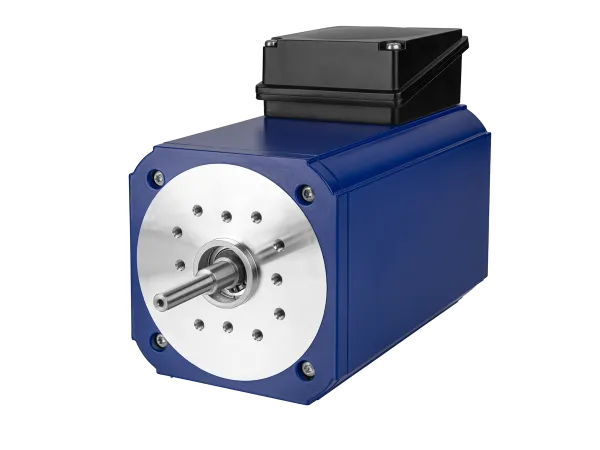

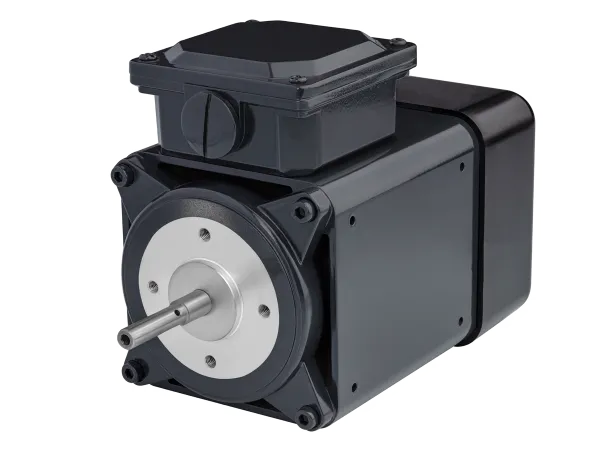

AC-Motors

Three and single-phase motors

Typical induction motors are suitable for both three-phase and single-phase current. Motors have a fixed speed, either 1,400 min-1 (4-pole) or 2,800 min-1 (2-pole). Advantages of these motors are a robust design as well as an excellent price-performance ratio. Through intensive development, Groschopp has succeeded in realizing a high power density in these motors, and as a result of this and their intelligent design, these motors are suitable for many versatile applications.

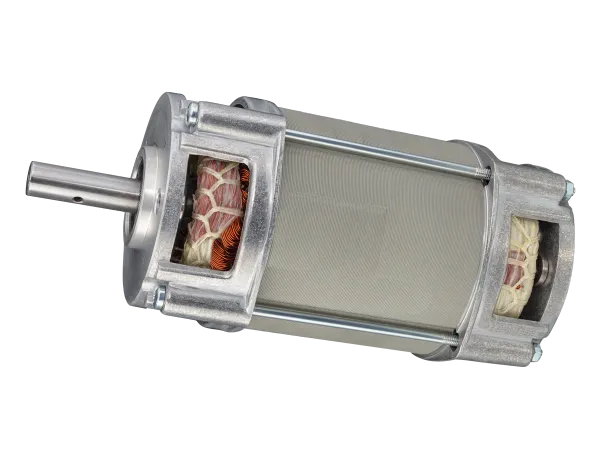

Induction motors usually have a distributed multi-strand winding in a stator. By applying a single- or three-phase current-feed, a rotating-field is generated (three-phase current, single-phase alternating current with capacitor) which causes the rotor to spin around.

Squirrel-cage rotor

The slots of the rotor are filled with a conductive metal end-to-end, and these rods are then short-circuited by means of a ring. That is why they are also called 'short-circuit-cage' or 'squirrel cage', hence, these motors are also identified as squirrel-cage- or short-circuit cage-motors.

Induction motors

The rotating-field of the stator induces currents into the squirrel cage of the rotor. That is why they are called 'induction motor'.

Asynchronous motor

The induced rotor currents generate magnetic poles, which follow the rotating-field of the stator. Rotor currents are only induced, when the rotor moves relative to the rotating-field of the stator according to the law of induction, which means that a torque force can only be generated when such rotor turning is not synchronous relative to the rotating-field of the stator. That is why those motors are also called asynchronous motors.