Groschopp News & Press

Groschopp produces samples and series components with 3D printers

Just a few years ago, 3D printing was mainly used in prototype construction. This has now changed. Thanks to the use of ever-improving printers and materials, this technology can now be used to create functional components. In the meantime, it has even established itself as an economical alternative in small series production. The drive experts at Groschopp AG Drives & More also use the advantages of 3D printing.

Groschopp motors, gearboxes and controllers as well as all drive components and parts are designed and manufactured at the Viersen site. The Research & Development department is the basis for the creation of innovative and successful drive concepts. The products are continuously tested and further developed in the in-house laboratory and prototype construction.

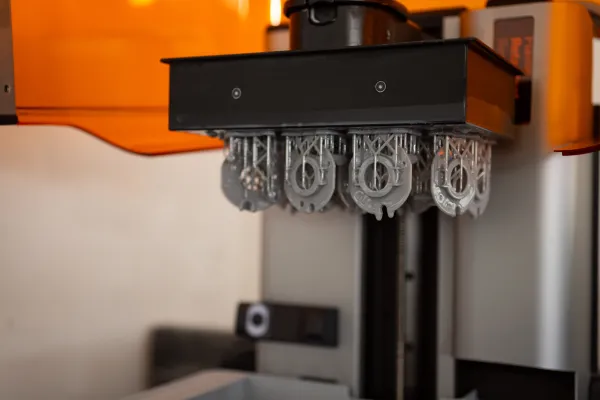

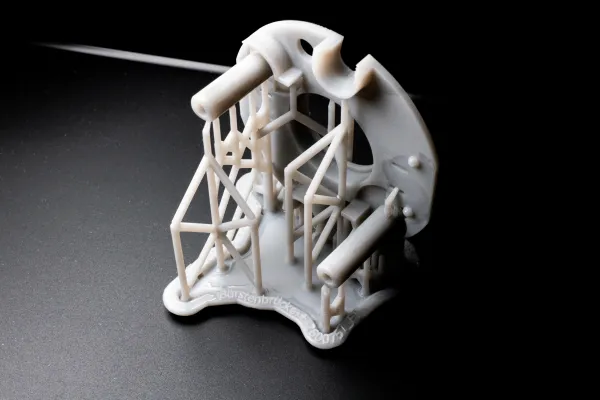

The company uses 3D printing for the production of prototypes and samples - but also for the production of series components for its engines and gearboxes as well as assembly devices. Groschopp was already using an FDM (Fused Deposition Modeling) printer for the robust, temperature-resistant plastic ABS in 2012. Today, the manufacturer has a modern MSLA printer (Masked Stereolithography Apparatus) - a resin 3D printer that projects UV light through an LCD mask to cure liquid synthetic resin layer by layer. This enables the drive specialists to print parts with different materials and properties. “A major advantage of this technology is its rapid availability,” explains Alexander Klupp, Head of Design at Groschopp. “Development projects can be completed more quickly and customers can be supplied with samples faster - the same applies to small series where it would not be economical to produce a tool.”

What role will 3D printing play in the future?

“In the future, products from 3D printers will increasingly replace conventionally manufactured parts, although they will not completely replace them,” says Klupp. “Both the printers and the materials required have become cheaper, meaning that 3D-printed parts can now be produced cost-effectively.” Another advantage is that they can be designed more freely than in conventional production. Even complex components can be produced quickly, easily and with little material using 3D printing - without having to compromise on functionality - which is an advantage both in prototype construction and in small series production. In addition, the number of parts can be reduced, which in turn lowers production and assembly costs.