Groschopp News & Press

Custom drives in mass production

Induction Motors from Groschopp in Coffee Grinders

Many people like to start their day with freshly ground coffee. Every coffee machine requires a specific grinder. Groschopp AG offers custom-made drive systems that can be adapted to the unique requirements of each application – for example, for coffee machines in commercial vending machines or industrial systems.

The drive specialist Groschopp from Viersen not only manufactures motors in small and medium quantities, but also in large series. In 2016, Groschopp received an order for 4,000 induction motors to be used as drives in the grinders of coffee machines, which were to be deployed globally in commercial settings and the hospitality industry. In 2021, the manufacturer was able to bring the product to series production and began manufacturing in 2022.

Development and Services

"Thanks to our high level of manufacturing depth at Groschopp, we can ideally tailor our solutions to the specific requirements of our customers," reports Andre Coolen-Pearse.

"‘Often, the machine is developed first – and only then is a suitable motor sought – in which case, a standard motor cannot be used.’ The motor to be developed must be specifically tailored to the application’s requirements. This approach increases efficiency and reduces costs.

Groschopp supports its customers as an OEM supplier from development to series production, considering its in-house research and development as the foundation for market success. To create new innovative products or customer-specific concepts, a team of highly qualified employees works across disciplines: from development and design to manufacturing, product management, and sales.

The electrical drive design is calculated in advance using innovative software tools and analysis methods, while motor designs are carried out through CAD programs. Through precise simulation, customer-specific requirements can be identified up to 95% in advance, and solutions can be implemented in a very short time.

The in-house prototype workshop and laboratory enable not only the production of prototypes in the traditional sense but also rapid prototyping, as well as extensive testing and long-term durability tests of the drive system during the development phase."

Induction Housing Motor for the Coffee Grinder

"For driving the coffee grinder, the grinder manufacturer opted for the AC induction motors of the IGKU90-60 series, which are known for their compact, robust design, reliability, and high power density," reports Coolen-Pearse. Thanks to the closed housing, they are resistant to external influences. When designing the motor, the focus was on implementing specific technical features to meet the application’s requirements.

The Coffee Machine Features Two Grinders with a Power Output of 550 Watts Each

"The biggest challenge was to achieve the required power in a compact space," explains Coolen-Pearse. To meet these demands, adaptations were made to the motor design, such as custom flange and shaft shapes for the grinder application. A special motor winding also ensured relatively high power output despite the compact design. Additionally, specific customer requirements regarding electrical design or mechanical adjustments were incorporated.

Moreover, it was essential to comply with specific standards in the food sector, as well as implement safety and fire protection regulations. The motors are also UL/CSA certified for use in the USA and Canada.

General Advantages of Groschopp’s AC Housing Motors

Groschopp’s AC housing motors offer high efficiency and smooth surfaces. This makes them easy to clean and suitable for use in areas with high hygiene standards, such as food processing, without the need for additional coatings. Thanks to their closed housing and convection cooling, the induction motors achieve protection class IP65, making them resistant to external influences and suitable for use in various environments. If required, the housing can be painted, hard-coated, silicone-coated, or made from stainless steel. Additionally, the IG series can be combined with different gearboxes and decentralized frequency converters.

Manufacturing on Demand

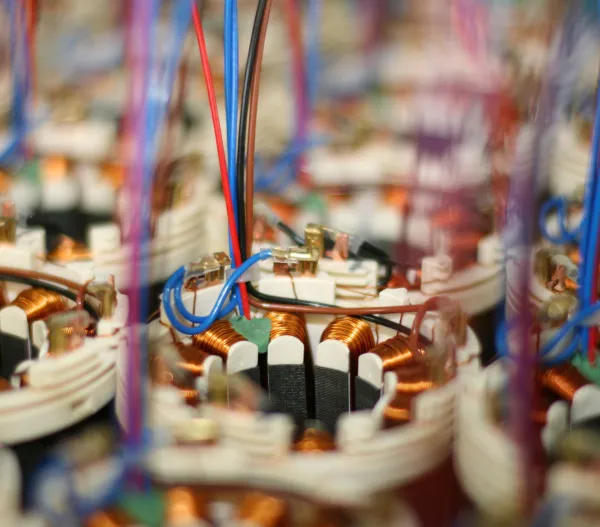

The components of Groschopp's drive systems are produced using state-of-the-art machines and automated production lines. For electronically commutated motors, there is a fully automated winding line, and for all other motors, fully automated production lines for pole coils and armature winding are available.

This ensures efficient and fast production, from small to large series, as well as high flexibility for special requirements. In addition, a systematic endurance test in a separate run-in area guarantees the high standard of Groschopp’s drive systems.

Continuous investments in modern manufacturing facilities, including CNC machining, winding centers, and assembly, enhance the company's efficiency and flexibility. Seamless collaboration with design and development unlocks innovation potential in production. Groschopp is a pioneer in the field of tooth coil winding, which enhances the efficiency and power density of motors.

Flexible Manufacturing Capacities and Short Delivery Times

"With our large machine parks, we have high production capacities both in Germany and at our plant in China," reports Andre Coolen-Pearse. "We are well-positioned." For the grinder drive project, part of the motors, as well as the coffee grinders themselves, were manufactured in China.

Thanks to the flexible expandability of manufacturing capacities, combined with decades of experience and commitment, the manufacturer was able to achieve particularly short delivery times for this order. The first motors were delivered within two months, and the complete order was fulfilled in four months by September 2022—despite initial expectations of a delivery time of nine months to a year, due to the inclusion of some specialized parts.

Collaboration with Perspective

Overall, the company distinguished itself in the order by demonstrating a high level of technical expertise, good consultation, quick response and delivery times, and close customer relationships. This was reflected in the positive feedback from the customer. "The customer was very satisfied with the results, and we are already working on a follow-up order for the delivery of another 4,000 motors this year," says Andre Coolen-Pearse. "Plans are also underway for an annual demand of 10,000 to 18,000 motors in 2025 for this custom series product." Groschopp will continue to support the grinder manufacturer’s project over the next five years and will also be available as a contractual partner for the development of further customized solutions.

Through orders like these, Groschopp has established itself as a key supplier of drive systems in the milling industry and will also develop motors for coffee grinders in other applications in the future. For example, for commercial or industrial coffee grinders, as well as grinders for laboratory and medical technology. "Depending on the request, we build drives for all types of grinders," concludes Coolen-Pearse. "We not only have extensive know-how and years of experience in motor development for the food industry, but also in areas such as centrifuges for medical or laboratory technology—especially when it comes to achieving high speeds and torque with low noise or minimal space requirements, as well as fine-tuning ball bearings, motor run-out, or using gray cast parts—whatever the customer needs."